Guest Writer | Chris Davis of Lower 48 Instruments

Our technicians turn dozens of delicate terminations on instrumentation and controls on a daily basis. It becomes incredibly important that we are able to exercise fine level control on these terminations as too much will leave us with an expensive repair, not enough will cause signal failure to potentially critical operations.

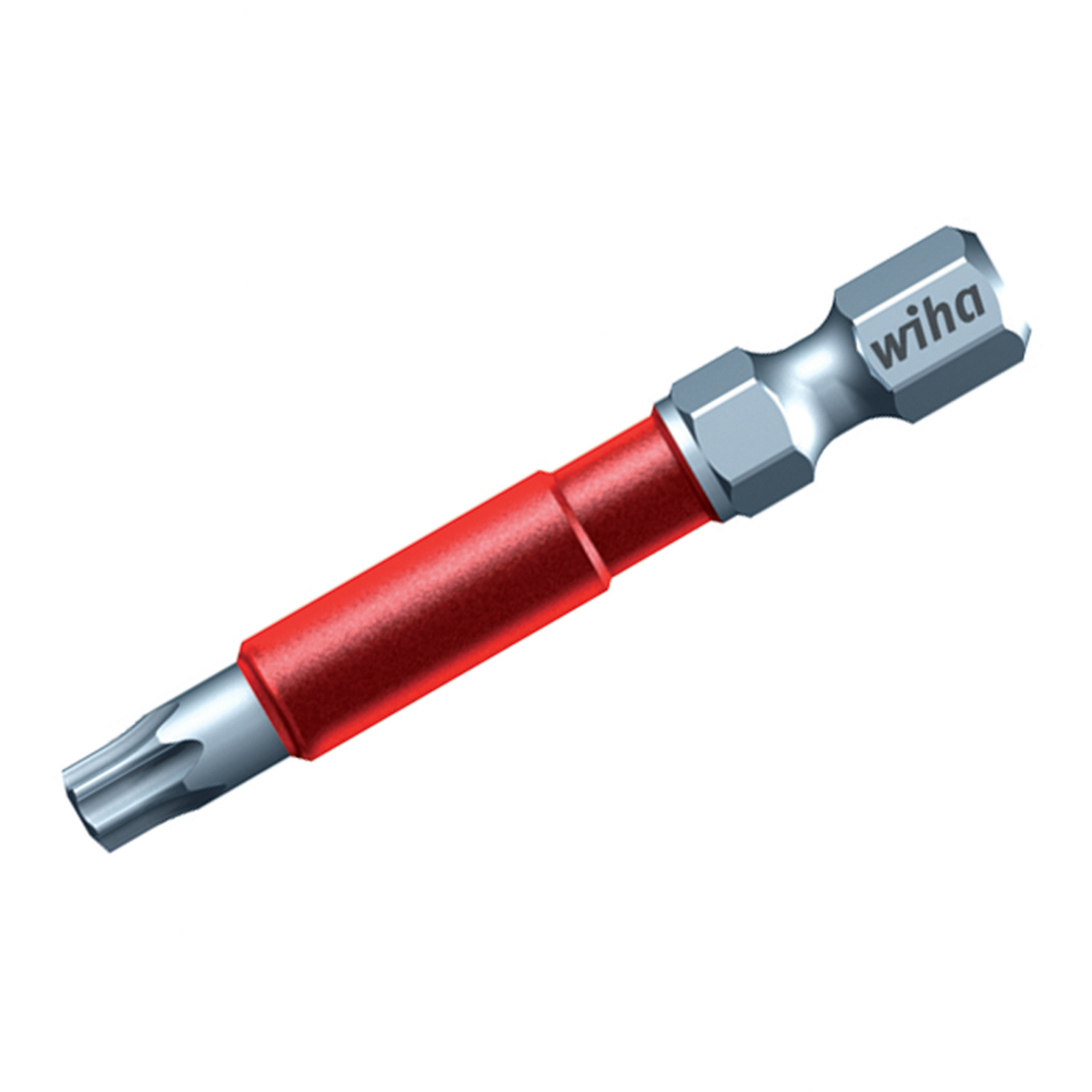

So with the line between success and failure being so fine, it is only natural that we choose the finest tools available for the task, the Wiha PicoFinish insulated drivers. Our owner was first exposed to Wiha years ago when one of his vendors provided him a driver as a gift. Being who he is, the first thing he did was modify the driver by grinding the tip to accommodate his need for a 2.5mm width blade. Some time later, he discovered the new PicoFinish Insulated 5pc Set from Wiha, so now there is no excuse for "custom grinds."

The other thing all of us appreciate about these drivers is the deep marking on the spinner cap. Because we service sewage plants frequently, we disinfect our tools at the end of every job. Due to that process, we find that many of our tools end up loosing their markings within weeks of purchase. Our last set of these drivers has been in use for more than 3 months and so far the markings are as crisp as new!

We all agree that these drivers are many times overlooked as there are more fancy headline grabbers, but with their fully hardened tool steel (which stands up to abuses like using the instrument driver as case openers) and full length molded insulation that is rated to 1000V they are one of our favorites. These tools give us maximum confidence that no matter what we find when we open a case, our drivers will keep us safe.

Find the Insulated PicoFinish Precision Drivers here.

Chris Davis’ Tool Bag with Wiha Tools Insulated Screwdrivers

points

points